Stainless steels are a iron-based alloy containing at between 10.5% to 30% Cr.  We don't save this data. %PDF-1.6

%

While the cuts come from turning, milling, disc grinding, and more. Engineering Standards The surface roughness is the measure of the total spaced irregularities on the surface. 1.8 .

We don't save this data. %PDF-1.6

%

While the cuts come from turning, milling, disc grinding, and more. Engineering Standards The surface roughness is the measure of the total spaced irregularities on the surface. 1.8 .

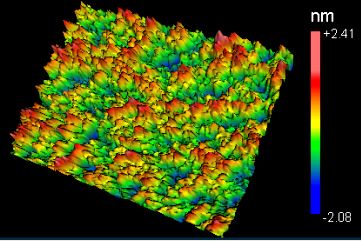

Average Ra may generally be up to 1 m* 4 The physical probes can then be switched with optical sensors or microscopes. EN ISO 4288:1997 Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996), [6] 1B bypass .  To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. No worry. Cookies are only used in the browser to improve user experience. This is a highly reflective, smooth finish, typically produced by polishing with successively finer grit abrasives, then buffing. And lay refers to the direction the predominant surface Alloying metallic elements added during the making of the steel increase corrosion resistance, hardness, or strength. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. 0.5 . All information and uploads are secure and confidential. The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses. Conversely, there is a degree of roughness that can give room for desired adhesion. Machinists use this where rings and packings have to slide across the surface grain. Incredibly important for corrosion and chemical resistant effects. Marks' Standard Handbook for Mechanical Engineers 11th Edition, Drawn Brass, Copper, Stainless Steel (New). It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness plays a very crucial role to determine how a product reacts with its environment. Geometrical Product Specifications (GPS) Indication of surface texture in technical product documentation (ISO 1302:2002).

To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. No worry. Cookies are only used in the browser to improve user experience. This is a highly reflective, smooth finish, typically produced by polishing with successively finer grit abrasives, then buffing. And lay refers to the direction the predominant surface Alloying metallic elements added during the making of the steel increase corrosion resistance, hardness, or strength. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. 0.5 . All information and uploads are secure and confidential. The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses. Conversely, there is a degree of roughness that can give room for desired adhesion. Machinists use this where rings and packings have to slide across the surface grain. Incredibly important for corrosion and chemical resistant effects. Marks' Standard Handbook for Mechanical Engineers 11th Edition, Drawn Brass, Copper, Stainless Steel (New). It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness plays a very crucial role to determine how a product reacts with its environment. Geometrical Product Specifications (GPS) Indication of surface texture in technical product documentation (ISO 1302:2002).

The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration. 1.3 . Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. There are different processes in examining the machining surface finish chart. Rough and dull.

If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. The results indicated that gas pipelines are more sensitive to the absolute roughness value. WebThe surface roughness of the machined surface was measured via portable surface roughness. f = friction factor

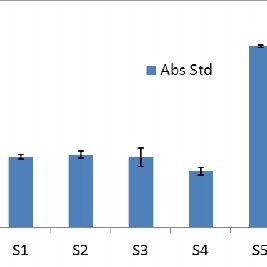

Please try again. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. Stainless steels are available in the form of. EN ISO 13565-1:1997. Roughness for different materials can be determined by experiments. Absolute Roughness is usually defined for a material and can be measured experimentally. EN 10088-2, Stainless steels Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steel for general purposes, [12] Some of our partners may process your data as a part of their legitimate business interest without asking for consent. Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. 1.0 . A skilled operator can generally blend this finish.  This article provides some typical absolute roughness values for common conduit materials. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. 1. Civil Engineering This table compares the different surface roughness scales for manufacturing processes. Thermodynamics Some of our calculators and applications let you save application data to your local computer. The principle of measuring root-mean-square roughness (Rq) [8], Stainless Steel in the Food and Beverage Industry, http://en.wikipedia.org/wiki/Surface_roughness, http://www.engineersedge.com/surface_finish.htm, http://www.rubert.co.uk/faqs/roughness-parameters/, http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, http://www.ssina.com/finishes/sheetsamples.html, https://kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf. Rigid pipe support is designed to allow no movement in at least one direction. Hardware, Metric, ISO As already mentioned, there are three basic components of a surface, roughness, waviness, and lay. to make a surface cleanable to microbial level, EHEDG is recommending an Ra of below 0.8 micrometer, in absence of crevices, scratches etcetera. 1.8 . From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Breaks and corrosion occurring in these sites could then cause the material to wear easily. And lay refers to the direction the predominant surface Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! In this study, the absolute roughness of various pipeline samples was measured using a Mitutoyo SJ-201 surface roughness gauge. This roughness parameter is best used for anomalies such as burrs and scratches. Specific Roughness A high-grade machine finish, which needs close control.

This article provides some typical absolute roughness values for common conduit materials. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. 1. Civil Engineering This table compares the different surface roughness scales for manufacturing processes. Thermodynamics Some of our calculators and applications let you save application data to your local computer. The principle of measuring root-mean-square roughness (Rq) [8], Stainless Steel in the Food and Beverage Industry, http://en.wikipedia.org/wiki/Surface_roughness, http://www.engineersedge.com/surface_finish.htm, http://www.rubert.co.uk/faqs/roughness-parameters/, http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, http://www.ssina.com/finishes/sheetsamples.html, https://kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf. Rigid pipe support is designed to allow no movement in at least one direction. Hardware, Metric, ISO As already mentioned, there are three basic components of a surface, roughness, waviness, and lay. to make a surface cleanable to microbial level, EHEDG is recommending an Ra of below 0.8 micrometer, in absence of crevices, scratches etcetera. 1.8 . From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Breaks and corrosion occurring in these sites could then cause the material to wear easily. And lay refers to the direction the predominant surface Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! In this study, the absolute roughness of various pipeline samples was measured using a Mitutoyo SJ-201 surface roughness gauge. This roughness parameter is best used for anomalies such as burrs and scratches. Specific Roughness A high-grade machine finish, which needs close control.

The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. EN ISO 5436-2:2012. The finish of a product indicates the performance of its components. WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Typically, very faint buffing or polishing lines may still be visible on the final product. Control of surface roughness can be performed quickly and easily using the simplified procedure for roughness inspection given in Annex A, EN ISO 4288 [5], [6]. 2. EN ISO 13565-2:1997. Selection of stainless steels are in general based on. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. For example, the absolute roughness of smooth looking aluminum pipes is around 0.001 mm.  KD^AnMZ8-*g'E4EFfLOt4%s2 iaV*ATSc#) MRsn,Jgz. It is also used for parts subject to vibrations, loads, and high stress. In practice, it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for purpose [1]. Older documents and surface roughness measuring instruments may still refer to Rz according to the 1984 version of this standard, which indicated the ten point height of irregularities. Then, therell be altering and reflection of the sound waves back to the device.

KD^AnMZ8-*g'E4EFfLOt4%s2 iaV*ATSc#) MRsn,Jgz. It is also used for parts subject to vibrations, loads, and high stress. In practice, it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for purpose [1]. Older documents and surface roughness measuring instruments may still refer to Rz according to the 1984 version of this standard, which indicated the ten point height of irregularities. Then, therell be altering and reflection of the sound waves back to the device.  Factor, , mm (ft), Surface Roughness for Various New Polyethylene Pipes (PE Pipes). The most widely used martensitic (plain chromium stainless class with exceptional strength) stainless steel, featuring the high level of strength conferred by the martensitics. This article provides some typical absolute roughness values for common conduit materials. Continue with Recommended Cookies. EN ISO 3274:1997. The Ra surface finish chart is also one of the most used for absolute values. Indeed, recent studies have suggested overestimation of the pressure drop across a pipeline during design resulting in less accurate cost estimates for pipeline projects. Rodriguez, V., Sukumaran, J., Ando, M., De Baets, P., Roughness measurement problems in tribological testing, Sustainable Construction and Design 2011, [5] Also the notation is important: Ra 0.5 m, for instance, does not have the same meaning as Ra max 0.5 m. Electric Motor Alternators WebRoughness for different materials can be determined by experiments. Search for other works by this author on: You can access this article if you purchase or spend a download. "

bz:D." }Az69

E/k+{q72Av73

A3Bj/-Vx1&d~WWQ(u=A7\1JdJ*JSwP(}Y6o Gt`/j0 B]-)A,1'f"rV"bju[I*D-vvVA~UY]xR h\7>oYw/gT[4|Es,}e/#URP9*Z=nkMDnF:U=!B{k3_Z2Pe-9v_Z!Rt1=`\/|[;c4I'dB At RapidDirect, we offer full dimensional inspection reports, so you can be sure of desired results. RapidDirect is your best choice for quality surface finishing services at the best prices. This is an explanatory copy of the title. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. (1981, May). Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. Engineering Calculators WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. Then, the parametric value determined can help find out comparative roughness parameters. A general description of several ways of cleaning are given. ASTM A 480/480M, Standard Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip, [11] document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Surfaces in manufacturing applications must remain within desired roughness limits to ensure the optimum quality of parts. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. 2. Smooth.

Factor, , mm (ft), Surface Roughness for Various New Polyethylene Pipes (PE Pipes). The most widely used martensitic (plain chromium stainless class with exceptional strength) stainless steel, featuring the high level of strength conferred by the martensitics. This article provides some typical absolute roughness values for common conduit materials. Continue with Recommended Cookies. EN ISO 3274:1997. The Ra surface finish chart is also one of the most used for absolute values. Indeed, recent studies have suggested overestimation of the pressure drop across a pipeline during design resulting in less accurate cost estimates for pipeline projects. Rodriguez, V., Sukumaran, J., Ando, M., De Baets, P., Roughness measurement problems in tribological testing, Sustainable Construction and Design 2011, [5] Also the notation is important: Ra 0.5 m, for instance, does not have the same meaning as Ra max 0.5 m. Electric Motor Alternators WebRoughness for different materials can be determined by experiments. Search for other works by this author on: You can access this article if you purchase or spend a download. "

bz:D." }Az69

E/k+{q72Av73

A3Bj/-Vx1&d~WWQ(u=A7\1JdJ*JSwP(}Y6o Gt`/j0 B]-)A,1'f"rV"bju[I*D-vvVA~UY]xR h\7>oYw/gT[4|Es,}e/#URP9*Z=nkMDnF:U=!B{k3_Z2Pe-9v_Z!Rt1=`\/|[;c4I'dB At RapidDirect, we offer full dimensional inspection reports, so you can be sure of desired results. RapidDirect is your best choice for quality surface finishing services at the best prices. This is an explanatory copy of the title. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. (1981, May). Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. Engineering Calculators WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. Then, the parametric value determined can help find out comparative roughness parameters. A general description of several ways of cleaning are given. ASTM A 480/480M, Standard Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip, [11] document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Surfaces in manufacturing applications must remain within desired roughness limits to ensure the optimum quality of parts. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. 2. Smooth.  Carbon Steel (Black Iron) - used for flues, stacks, hoods, high temperature industrial systems. Therefore, it is the best finish in gauge and instrument works. ^O=`

?'2PV1iB8UCQ@(98-G)H>13V%7wQ)^01(T1>jv" Figure 1 - Typical hydraulic system layout. Type 304 is available in virtually all product forms and finishes. Stainless Steel - used for kitchen exhaust, moisture laden air and fume exhausts. Relative roughness factor is often used for pressure drop calculations for pipes and other equipment. If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. 2.0 . Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. EN ISO 5436-1:2000. 'Absolute Pipe Roughness' () is a measure of pipe wall irregularities of commercial pipes. You can download Pipe Flow Expert for a free trial and see how it makes it easy to draw, design and calculate the flows and pressure drops in your pipe system. Whenever machinists talk about surface finish, they often refer to surface roughness.

Carbon Steel (Black Iron) - used for flues, stacks, hoods, high temperature industrial systems. Therefore, it is the best finish in gauge and instrument works. ^O=`

?'2PV1iB8UCQ@(98-G)H>13V%7wQ)^01(T1>jv" Figure 1 - Typical hydraulic system layout. Type 304 is available in virtually all product forms and finishes. Stainless Steel - used for kitchen exhaust, moisture laden air and fume exhausts. Relative roughness factor is often used for pressure drop calculations for pipes and other equipment. If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. 2.0 . Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. EN ISO 5436-1:2000. 'Absolute Pipe Roughness' () is a measure of pipe wall irregularities of commercial pipes. You can download Pipe Flow Expert for a free trial and see how it makes it easy to draw, design and calculate the flows and pressure drops in your pipe system. Whenever machinists talk about surface finish, they often refer to surface roughness.  These are rough, low-grade surfaces resulting from coarse feeds and heavy cuts. Swierzawski, Tadeusz J. There are different methods and equipment involved in measuring surface roughness. Machining processes such as turning, milling, and grinding will depend on multiple factors. Pipe materials in the Pipe Flow Expert pipe database include Cast Iron (Class A,B and C), Copper Tube (Type X,Y,K,L,M), HDPE (SDR 7.3 to SDR 26), PVC (Schedule 40, 80, and CL100 to CL315), Stainless Steel (Schedule 5s, 10s, 40s), Steel (Schedule 40,80,160) and more. Furthermore, liquid pipelines with relatively high Reynolds number are more likely to undergo noticeable capacity loss because of absolute roughness increases due to pipe degradation. Absolute Roughness (k) is a measure of pipe wall irregularities. The machinist then uses a registered profile to determine roughness parameters. In architectural applications where surface appearance is of great importance roughness values alone are insufficient to characterise a surface. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter.

These are rough, low-grade surfaces resulting from coarse feeds and heavy cuts. Swierzawski, Tadeusz J. There are different methods and equipment involved in measuring surface roughness. Machining processes such as turning, milling, and grinding will depend on multiple factors. Pipe materials in the Pipe Flow Expert pipe database include Cast Iron (Class A,B and C), Copper Tube (Type X,Y,K,L,M), HDPE (SDR 7.3 to SDR 26), PVC (Schedule 40, 80, and CL100 to CL315), Stainless Steel (Schedule 5s, 10s, 40s), Steel (Schedule 40,80,160) and more. Furthermore, liquid pipelines with relatively high Reynolds number are more likely to undergo noticeable capacity loss because of absolute roughness increases due to pipe degradation. Absolute Roughness (k) is a measure of pipe wall irregularities. The machinist then uses a registered profile to determine roughness parameters. In architectural applications where surface appearance is of great importance roughness values alone are insufficient to characterise a surface. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter.  All rights reservedDisclaimer |

All rights reservedDisclaimer |  This article provides some typical absolute roughness values for common conduit materials. Design & Manufacturability Only emails and answers are saved in our archive.

This article provides some typical absolute roughness values for common conduit materials. Design & Manufacturability Only emails and answers are saved in our archive.