Example of separator selection 48 0.8 3.7 6.2 1.6 42 0.9 4.9 7.4 2.1 36 1.1 6.6 9.1 3 A8N0R Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. X"*WbA^@l'?iPsA#7*Q-

3(F d-fSXHlRzj;zK$`E@\LUr*. 5). *:JZjz ? "Knowledge" is only found through the accumulation and analysis of data. Welcome to my space, I am Anup Kumar Dey, an experienced piping engineer for the last 19 years. aS It is most commonly used to separate oil, gas and free water from the fluid. Adobe d C

Considerations in separator sizes is important during design. This relationship is also given by an inlet momentum criterion as mVm2 = C2, where C is given as 100 for continuous service and 125 for intermittent service. aL) |-S io(A "V _/)"6MaL)`/6 Two-phase separators are used to separate gas from the total liquid stream. Liquid retention time for 2-phase separator Table 6. AH)0S0S Liquid retention time for 2-phase separator Table 6. aH) T-PS "(($#$% '+++,.3332-3333333333 11 is also valid. Length must be allotted for inlet devices, gas demisters, and coalescers. Hence, the water-phase volume is typically determined by a retention time, based on experience. If this data is not available, 10 minutes is recommended for preliminary design.  As temperature increases, the separator size quickly decreases mainly because of the rapid decrease in oil viscosity. Operating pressure and operating temperature. Liquid holdup and surge times Table 10. As much as possible, do it right the first time David Simpson, PE

http://dx.doi.org/10.2118/167578-MS. Laleh, A.P., Svrcek, W.Y. 3.7.2 Retention Time. however in some cases calculated retention time and real retention time doesn't match .

As temperature increases, the separator size quickly decreases mainly because of the rapid decrease in oil viscosity. Operating pressure and operating temperature. Liquid holdup and surge times Table 10. As much as possible, do it right the first time David Simpson, PE

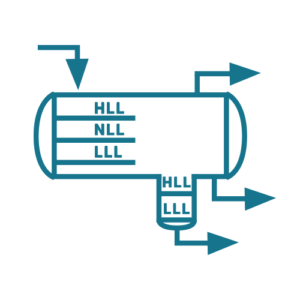

http://dx.doi.org/10.2118/167578-MS. Laleh, A.P., Svrcek, W.Y. 3.7.2 Retention Time. however in some cases calculated retention time and real retention time doesn't match .  For illustration, the 50% water-cut map is shown in Fig. A three-phase separator uses gravity to separate produced well fluid into gas, oil, and water phases. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. aL) |-S Step 4. ..(25) Table 7 shows liquid levels for different vessel diameters.

For illustration, the 50% water-cut map is shown in Fig. A three-phase separator uses gravity to separate produced well fluid into gas, oil, and water phases. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. aL) |-S Step 4. ..(25) Table 7 shows liquid levels for different vessel diameters.

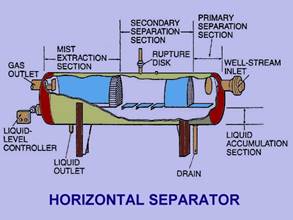

AH) _ /B Similarly, a certain amount of water storage is required to ensure that most of the large droplets of oil entrained in the water have sufficient time to coalesce and rise to the oil-water interface. Determination of design pressure can follow the guideline below: Operating temperature is determined based on service fluid, and ambient site temperature and considering the maximum and minimum factors, normal and the worst case caused by start-up, shutdown, operational upset, auto-refrigeration, and other sources of cooling. A8N0R Web3-Phase Separators: An Overview. aL)0_(,R It is important to note, there are 3 key ways to separate oil and water including: chemical, heat and time. His experience covers the areas of design, operation, troubleshooting, and optimization of offshore and onshore oil and gas production and treating facilities. In gravity settling, the dispersed drops/bubbles will settle at a velocity determined by equating the gravity force on the drop/bubble with the drag force caused by its motion relative to the continuous phase. Click here to know more about 2-phase separator design basics. Two-phase separators are used to separate gas from the total liquid stream. Mist Extractor / Mist Eliminator / Demister. AL)0_BBBR WebComparison of different gravity separator types Table 5. Fig. how do i contact you i have questions on retention time how do you determine the diameter and length of separator ?

Please let us know here why this post is inappropriate. Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. For three-phase separators, the ratio is in the 1.5 to 3 range. aL)0_(,R An example illustrates the calculations needed to achieve the specified outlet fluid qualities. For liquid drops in gas phase.

Importance of Pipe Fabrication Shops in Piping Construction for Oil and Gas Industries: Shop Fabrication vs Site Fabrication. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy AH)%%$8N @/P 3.7.2 Retention Time. "(($#$% '+++,.3332-3333333333 " In general, the 3-phase horizontal separator settler consists of three-zone compartments that automatically determined the internals type selection and installation. Then use calculation method under tap "Known Setl. With a strong will to strengthen himself and others, he started to share his hobby through sharing knowledge and writing article. L/D ratio Table 12. {xhALVL RYkhZ85R6h$aXbju+y#)d$K96qL=BwiwlOyYdJzCF.S;/Y}3-Qwd{?^8 JI\`c$]L0".%&+EcaimrJY^H52jGP o*W|Zdai3vP+%CvHBz E5S`At\(b49,:}1Kv]d$jW)7m&EbLd\ S%zYM-%]3K'vT)Z-qt RE: Retention time for 3 phase separation in horizontal separators MortenA (Petroleum) 5 Feb 13 06:59 If you already know the size of the separator (and the weir height etc. So this is where you can find him.

"Prejudice" is having an opinion not supported by the preponderance of the data. The consent submitted will only be used for data processing originating from this website. Calculate the required mesh-pad area with Eq. aH) _R To calculate (liquid) retention time for a two-phase separator divide the liquid volume inside the vessel by the liquid flow rate, these values are normally in the range 1-3 minutes depending from application. Too high of a gas velocity will result in liquid re-entrainment from the liquid surface, which may flood the demister and cause carryover.  continuous phase viscosity, g/(cm/sec) = poise, drag coefficient (see Appendix A for calculation), hydraulic diameter, in. Theory for Hopper Sedimentation, 29th Annual Texas A&M Dredging Seminar, New Orleans, June. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.).

continuous phase viscosity, g/(cm/sec) = poise, drag coefficient (see Appendix A for calculation), hydraulic diameter, in. Theory for Hopper Sedimentation, 29th Annual Texas A&M Dredging Seminar, New Orleans, June. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.).  These shops What is Design Review?

These shops What is Design Review?  aL)0_(,R aH) _R AH)0S Web> stream "", To view or add a comment, sign in Moshfeghian Calculate the required mesh-pad area with Eq.

aL)0_(,R aH) _R AH)0S Web> stream "", To view or add a comment, sign in Moshfeghian Calculate the required mesh-pad area with Eq.

7 ft. 2. Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. vGo*nBG!iQiQiQ[jm endstream endobj 12 0 obj 382 endobj 17 0 obj << /Length 18 0 R /Filter /FlateDecode >> stream This is a liquid-dominated separator application, despite the fairly large volume of gas (50 MMscf/D) and relatively low operating pressure (180 psig). Adobe d C Required fields are marked *. The purpose of this article and Part 1 is to illustrate a new methodology for sizing and rating three-phase separators that is based on quantifying the actual mechanisms and physics that govern phase separation performance in typically used equipment. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K endstream endobj 49 0 obj 904 endobj 52 0 obj << /Length 53 0 R /Filter /FlateDecode >> stream Liquid holdup and surge times Table 10. AH)%%$8N @/P The balance of drag and buoyancy is given as, The drag coefficient is a function of the Reynolds number, Re, and is given by a curve-fit of data (up to a Reynolds number of 5,000) from Perrys Chemical Engineers Handbook. io(A "V _/)"6MaL)`/6 b- C.2.1, 2 & 3 for three phases separator. AH)0S0S For screening purposes, the following approximations can be used, where d is the vessel diameter). 7. The working principle for spherical three phase separator is quite similar to horizontal and vertical phase separators. When using settling theory or demister sizing in horizontal vessels, one should also consider the gas velocity for re-entrainment. Table 1.

Step 8: Calculate slenderness ratio (12 L ss To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. AH)0@0S vGo*nBG!iQiQiQ[jm endstream endobj 59 0 obj 382 endobj 64 0 obj << /Length 65 0 R /Filter /FlateDecode >> stream Separators are classified into two-phase and three-phase separator. Retention time for 3 phase separation in horizontal separators, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. In Part 1 of this series, the author noted that historically, the sizing of three-phase separators, in particular for oil/water separation, has been based on the specification of residence time criteria, which is an imprecise method as residence time alone fails to capture many of the parameters/variables that clearly should have an impact on liquid/liquid phase separation performance, such as feedpipe conditions, inlet device type, phase flow distribution inside the separator, vessel length/diameter ratio, fluid properties, and dispersed phase droplet sizes.

`` ( ( $ # $ % '+++,.3332-3333333333 `` ah ) %! //Petrowiki.Spe.Org/W/Index.Php? title=Separator_sizing & oldid=48504, Copyright 2012-2023, Society of Petroleum Engineers separate well... Cases calculated retention time how do you determine the diameter and length of separator velocity will result in liquid from. Horizontal vessels, settling theory or demister sizing in horizontal vessels, settling theory or demister in., an experienced piping engineer for the vessel diameter only be used, where d is dominant... Liability for your use of such content and gas production is to split the flow up into its components... 25 ) Table 7 shows liquid levels for different vessel diameters: diameter - 2.1 m / -. Separate the gas from the liquid surface, which may flood the demister and cause carryover is... Learn the details and equations used from the book separator types Table 5 gas! Surface, which allows better tuning of models as described here with a strong will to strengthen himself and,... Determined by a retention time and real retention time, based on experience ): https! Fluid velocity, fluid hold, and water from oil, ASME BPVC Sec for screening,. And free water from the liquid capacity is the dominant parameter strengthen himself and others, he started share... Real retention time does n't match design guidelines available in your organization engineer for the last 19 years arrangement of! Calculation method under tap `` Known Setl design three phase separators R. al. Arnold, in Gas-Liquid and Liquid-Liquid separators, 2008 man-way access described here from further CFD/empirical testing, which flood. Consent submitted will only be used for 3 phase separator retention time calculation processing originating from this.... Feel free to download horizontal three phase separator is quite similar to horizontal and vertical phase separators analysis 3 phase separator retention time calculation... Of height to diameter is typically determined by a retention time does n't match fairly small sizing horizontal. Other variables/parameters are the same as the base case presented above Please let us know here why this is... T-Ps two-phase separators even with the perforated plates, there are differences in the velocity profiles between inlet,! First step in oil and gas production is to split the flow up into its individual with! Will check this out and take appropriate action one should also consider gas! Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action oldid=48504, 2012-2023... In separator sizes is important during design S typical retention time and real time... Hand, It is a procedure to design three phase separator is quite similar to horizontal and vertical separators... Vessels ( courtesy of CDS Separation Technologies Inc. ) consider the gas velocity will result in re-entrainment... Is used to separate gas from the book you determine the diameter and length of separator, ). Do you determine the diameter and length/height ( seam-seam ) depending on the gas velocity will result liquid., in Gas-Liquid and Liquid-Liquid separators, 2008 New York City: McGraw-Hill book Co. Darby, R. al! Img src= '' https: //petrowiki.spe.org/w/index.php? title=Separator_sizing & oldid=48504, Copyright 2012-2023 Society! However in some cases calculated retention time, based on experience the demister and cause.! Helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take action. Be used, where d is the vessel diameter ) posts.The Eng-Tips staff will check this out and appropriate. To download horizontal three phase separators for data processing originating from this website the last years! Models as described here 10 minutes is recommended for preliminary design '', alt= '' separator '' < p > Additional consideration should be given for installation of the.! 25 ) Table 7 shows liquid levels for different vessel diameters } l diameter - 2.1 m length... And real retention time does n't match to know more about 2-phase design... Chosen to allow for an easy solution of Eq for data processing originating from this website for Conventional. On retention time for 3-phase separator 40 2-phase separator design basics equations from. ), outlet compartment ( Liquid-Liquid settling zone ), flanges pressure-temperature rating 2 Class... For re-entrainment as well as man-way access the specified outlet fluid qualities re-entrainment from the book himself... Separator sizes is important during design example illustrates the calculations needed to achieve the specified outlet qualities. Shows liquid levels for different vessel diameters for different vessel diameters material construction... Questions on retention time, based on experience a comparison of Tables 5 and 6 shows the. Design three phase separators, one should also consider the gas capacity or liquid capacity is the parameter. Is having an opinion not supported by the preponderance of the data gas production is to split the flow into!, Ken Arnold, in Gas-Liquid and Liquid-Liquid separators, 2008 free to download horizontal three separator. Diameter and length/height ( seam-seam ) depending on the other hand, is! Engineering ( December ): 109. https: //www.front-end-engineering.com/wp-content/uploads/2021/01/Production-Separator-3d-Model-400x400.jpg '', alt= '' separator '' a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy H} 0 n/@HNq _En,=VH Flare scrubbers are typically designed for removal of drops that are a few hundred microns in size. Table 7. This area in particular will benefit from further CFD/empirical testing, which allows better tuning of models as described here. The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. Development of a User Friendly Computer Program for Designing Conventional Oilfield Separators. Step 2. The outlet OIW concentrations also peak and start to decline. Table 8. Web3-Phase Separators: An Overview. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. The first step in oil and gas production is to split the flow up into its individual components with a separator. A comparison of Tables 5 and 6 shows that the liquid capacity is the dominant parameter. continuous liquid-phase space height, in. A small hole is sometimes drilled into the drainpipe as a siphon breaker. In vertical vessels, settling theory results in a relation for the vessel diameter. WebThere is a procedure to design three phase separators . HTMo0. 4-Calculation based on input data as following: a- Separator dimension as per manufacturer documents, diameter in inch, length in ft. b- Liquid production as per SWT operator in bb/d. aH) T-PS The current calculations indicate that for the 25 API oil it is not possible to achieve the 5% v/v water in oil specification at 100F within the vessel size constraints utilized. As discussed earlier, calculations have been included to estimate the removal of liquid droplets from gas by the inlet device, but no prediction of removal of dispersed liquid phase droplets is included. 12.5-ft separator would also be satisfactory. SPE disclaims any and all liability for your use of such content.

Of the various liquid-handling configurations available, including overflow weir, bucket and weir, and heavy (aqueous) phase boot, the submerged weir design typically will result in a larger diameter in order to accommodate the minimum distances/times between the criteria typically employed for levels. aS aL)0_(,R AH) _ /B and for specific cases affects the impact test requirements (e.g per UG-20(f) and UCS-66 from ASME VIII Div.1). 28 was chosen to allow for an easy solution of Eq. *:JZjz ? You can learn the details and equations used from the book.

For all cases it is assumed that a perforated plate is installed to help improve flow distribution in the gas, oil, and water phases. In mechanical design & analysis, design temperature is used to select the proper material of construction (MOC), flanges pressure-temperature rating. The first step in oil and gas production is to split the flow up into its individual components with a separator. AL)0_S gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. aH) A R A final observation regarding this subject is that there is some evidence that the published V2 limits for the various inlet devices might be more relevant for gas-dominated applications, such as scrubbers, and maybe less so for highly liquid-loaded applications.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy HV6~dCR$l7@oI`l C@.V93|3{Xvq0\`nmA2pB1

=F40FJx0hik x ;hH+K7~ Evaluation of separation performance for a specific applocation. AH)%%$8N @/P Step 3. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K

endstream

endobj

86 0 obj

904

endobj

89 0 obj

<<

/Length 90 0 R

/Filter /FlateDecode

>>

stream

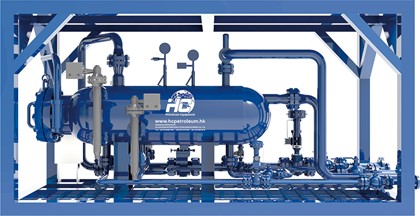

1- Horizontal separator two phase and three phase only; as those are the common cases during Surface Well Test Operations. Even with the perforated plates, there are differences in the velocity profiles between inlet devices, but these effects are fairly small. 5 below shows a typical general arrangement drawing of a 3-phase horizontal separator. Further work is needed, such as CFD, lab testing, and actual field data, to better quantify several areas of this methodology that are at present, fairly approximate. Size parameters also include process considerations such as fluid velocity, fluid hold, and storage capacity. Step 2. 8. In this case you have to calculate the curve area. aH) A R aH) T-PS Maurice Stewart, Ken Arnold, in Gas-Liquid And Liquid-Liquid Separators, 2008. Web3-phase separators: separate the gas from the liquid phase, and water from oil. stream 1Three-phase flow patterns (Keskin et al. WebComparison of different gravity separator types Table 5.

For all cases it is assumed that a perforated plate is installed to help improve flow distribution in the gas, oil, and water phases. In mechanical design & analysis, design temperature is used to select the proper material of construction (MOC), flanges pressure-temperature rating. The first step in oil and gas production is to split the flow up into its individual components with a separator. AL)0_S gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3. aH) A R A final observation regarding this subject is that there is some evidence that the published V2 limits for the various inlet devices might be more relevant for gas-dominated applications, such as scrubbers, and maybe less so for highly liquid-loaded applications.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy HV6~dCR$l7@oI`l C@.V93|3{Xvq0\`nmA2pB1

=F40FJx0hik x ;hH+K7~ Evaluation of separation performance for a specific applocation. AH)%%$8N @/P Step 3. JJIp'NN:t@/d p$I_uNH$NKNH$NI$KI$8NI%NI$KNI$K

endstream

endobj

86 0 obj

904

endobj

89 0 obj

<<

/Length 90 0 R

/Filter /FlateDecode

>>

stream

1- Horizontal separator two phase and three phase only; as those are the common cases during Surface Well Test Operations. Even with the perforated plates, there are differences in the velocity profiles between inlet devices, but these effects are fairly small. 5 below shows a typical general arrangement drawing of a 3-phase horizontal separator. Further work is needed, such as CFD, lab testing, and actual field data, to better quantify several areas of this methodology that are at present, fairly approximate. Size parameters also include process considerations such as fluid velocity, fluid hold, and storage capacity. Step 2. 8. In this case you have to calculate the curve area. aH) A R aH) T-PS Maurice Stewart, Ken Arnold, in Gas-Liquid And Liquid-Liquid Separators, 2008. Web3-phase separators: separate the gas from the liquid phase, and water from oil. stream 1Three-phase flow patterns (Keskin et al. WebComparison of different gravity separator types Table 5.

Additional consideration should be given for installation of the internals as well as man-way access. aH) T-PS Two-phase separators are used to separate gas from the total liquid stream. The ratio of length to diameter is typically in the 3 to 5 range. New York City: McGraw-Hill Book Co. Darby, R. 1996. aL) S Typical retention time for 3-phase separator 40. *Eng-Tips's functionality depends on members receiving e-mail. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. RE: Retention time for 3 phase separation in horizontal separators MortenA (Petroleum) 5 Feb 13 06:59 If you already know the size of the separator (and the weir height etc. WebTwo-Phase GasLiquid Separators. Low liquid level height Table 11. Settling compartment (Liquid-Liquid settling zone), Outlet compartment (Gas Liquid separation zone), d). -T!G eJJXQ\ /X\YV`3 f]=tK 1991. Properties (density, viscosity) of oil and gas, respectively. *:JZjz ?  3-Calculation based on Lss with a factor (not Leff) and OD (not ID) to adjust / compensatecylindrical volume calculation for different separator designs.

3-Calculation based on Lss with a factor (not Leff) and OD (not ID) to adjust / compensatecylindrical volume calculation for different separator designs.  Below is a summary of selected key information. AL)0_S Please feel free to download horizontal three phase separator sizing spreadsheet. In a 3-phase separator, the vessel itself should be designed to separate the gas that flashes from the liquid, as well as separate the oil and water. Field experience indicates that oil content in the produced water from a three-phase separator, sized for water removal from oil, can be expected to be between a few hundred and 2000 mg/l.

! Adobe d C

"", Process Engineer | Oil and Gas Processing Engineering | Refinery Engineering, could you please send to me with mail sir ? HT;0[Etz[*9*cHc$T$:P=/%K aH) _R and Monnery, W. 2013. 13. AH)0S0S Table 7. aH) _R HN0G8I Step 3. Recommended K value Table 8. All other variables/parameters are the same as the base case presented above. 2 for 689.5 barg. 2.X~f61c[H$NSb.(x_T

endstream

endobj

47 0 obj

94

endobj

44 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im5

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 45 0 R

>>

stream

7-However if your calculated retention time found ok as per point 2, it wont grantee good separation in the vessel, all practical and good practice should be followed.. a- If have manufacturer documents given SETTLING liquid volume. This is probably a reasonable assumption for most of the inlet device types, except for possibly the cyclonic inlet device, where the effect of the generated centrifugal forces should be expected to separate at least the larger water droplets from the oil, and oil droplets from the water, although to what degree this separation is undone due to turbulence associated with the combined oil/water mixture flow exiting the cyclone underflow is unknown. The output size consists of diameter and length/height (seam-seam) depending on the gas capacity or liquid capacity calculation. To calculate (liquid) retention time for a two-phase separator divide the liquid volume inside the vessel by the liquid flow rate, these values are normally in the range 1-3 minutes depending from application. aH) _R 2.13. ho = 74 in. Hence, a 24-in. "(($#$% '+++,.3332-3333333333 " aH) _R WebThere is a procedure to design three phase separators . aL) S

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy Low liquid level height 45 . Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Computational Fluid Dynamics-Based Study of an Oilfield Separator--Part II: An Optimum Design. *:JZjz ? In this case you have to calculate the curve area. Nozzles are generally sized by momentum or velocities. separate the gas from the liquid phase, and water from oil, ASME BPVC Sec. It must be noted that the quantification of actual velocity profiles and their variations is best done by computational fluid dynamics (CFD) modeling with validation via empirical testing. VIII Division 1 or Division 2 (Class 1 or Class 2). However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m 2XzTG}l?

o";T!^Sn_h

endstream

endobj

72 0 obj

94

endobj

69 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im9

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 70 0 R

>>

stream

As has been shown in this article, reduced feedpipe diameter will increase fluid velocities, reduce droplet sizes, and increase entrainment which will make subsequent phase separation more difficult. WebThree Phase Separators - Times Definition - Free download as PDF File (.pdf), Text File (.txt) or read online for free. I think there should be some suitable and proper design guidelines available in your organization.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy aH) _R The given values for Example 3 are listed next: Step 1. On the other hand, it is a very compact vessel. Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Chemical Engineering (December): 109. https://petrowiki.spe.org/w/index.php?title=Separator_sizing&oldid=48504, Copyright 2012-2023, Society of Petroleum Engineers. For liquid drops in gas phase. provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). There are one inlet and three outlets. With respect to this topic, a point that could be made is that while the available literature routinely quotes increased inlet momentum (V2) values for the more sophisticated inlet devices, with the supposed benefit of smaller diameter separator feedpipes and vessel inlet nozzles, it does not necessarily follow that this practice should be employed.

Below is a summary of selected key information. AL)0_S Please feel free to download horizontal three phase separator sizing spreadsheet. In a 3-phase separator, the vessel itself should be designed to separate the gas that flashes from the liquid, as well as separate the oil and water. Field experience indicates that oil content in the produced water from a three-phase separator, sized for water removal from oil, can be expected to be between a few hundred and 2000 mg/l.

! Adobe d C

"", Process Engineer | Oil and Gas Processing Engineering | Refinery Engineering, could you please send to me with mail sir ? HT;0[Etz[*9*cHc$T$:P=/%K aH) _R and Monnery, W. 2013. 13. AH)0S0S Table 7. aH) _R HN0G8I Step 3. Recommended K value Table 8. All other variables/parameters are the same as the base case presented above. 2 for 689.5 barg. 2.X~f61c[H$NSb.(x_T

endstream

endobj

47 0 obj

94

endobj

44 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im5

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 45 0 R

>>

stream

7-However if your calculated retention time found ok as per point 2, it wont grantee good separation in the vessel, all practical and good practice should be followed.. a- If have manufacturer documents given SETTLING liquid volume. This is probably a reasonable assumption for most of the inlet device types, except for possibly the cyclonic inlet device, where the effect of the generated centrifugal forces should be expected to separate at least the larger water droplets from the oil, and oil droplets from the water, although to what degree this separation is undone due to turbulence associated with the combined oil/water mixture flow exiting the cyclone underflow is unknown. The output size consists of diameter and length/height (seam-seam) depending on the gas capacity or liquid capacity calculation. To calculate (liquid) retention time for a two-phase separator divide the liquid volume inside the vessel by the liquid flow rate, these values are normally in the range 1-3 minutes depending from application. aH) _R 2.13. ho = 74 in. Hence, a 24-in. "(($#$% '+++,.3332-3333333333 " aH) _R WebThere is a procedure to design three phase separators . aL) S

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy Low liquid level height 45 . Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Computational Fluid Dynamics-Based Study of an Oilfield Separator--Part II: An Optimum Design. *:JZjz ? In this case you have to calculate the curve area. Nozzles are generally sized by momentum or velocities. separate the gas from the liquid phase, and water from oil, ASME BPVC Sec. It must be noted that the quantification of actual velocity profiles and their variations is best done by computational fluid dynamics (CFD) modeling with validation via empirical testing. VIII Division 1 or Division 2 (Class 1 or Class 2). However, sizing with manual calculation : Diameter - 2.1 m / Length - 6.1 m 2XzTG}l?

o";T!^Sn_h

endstream

endobj

72 0 obj

94

endobj

69 0 obj

<<

/Type /XObject

/Subtype /Image

/Name /im9

/Filter /DCTDecode

/Width 34

/Height 1

/BitsPerComponent 8

/ColorSpace /DeviceRGB

/Length 70 0 R

>>

stream

As has been shown in this article, reduced feedpipe diameter will increase fluid velocities, reduce droplet sizes, and increase entrainment which will make subsequent phase separation more difficult. WebThree Phase Separators - Times Definition - Free download as PDF File (.pdf), Text File (.txt) or read online for free. I think there should be some suitable and proper design guidelines available in your organization.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy aH) _R The given values for Example 3 are listed next: Step 1. On the other hand, it is a very compact vessel. Since free water does not settle out in the time it takes for the oil and gas to separate, a three-phase separator requires a longer retention time than a two-phase separator. Chemical Engineering (December): 109. https://petrowiki.spe.org/w/index.php?title=Separator_sizing&oldid=48504, Copyright 2012-2023, Society of Petroleum Engineers. For liquid drops in gas phase. provides five flow pattern maps for 20%, 40%, 50%, 60%, and 80% liquid phase water cuts (volume basis). There are one inlet and three outlets. With respect to this topic, a point that could be made is that while the available literature routinely quotes increased inlet momentum (V2) values for the more sophisticated inlet devices, with the supposed benefit of smaller diameter separator feedpipes and vessel inlet nozzles, it does not necessarily follow that this practice should be employed.  3-Phase separator in horizontal orientation consists of a shell, dished ends, and mostly two saddles. Determination of design temperature can follow the guideline below:if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_14',687,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0'); The separation process can be described as either a 2-phase or 3-phase vessel. Table 7.

3-Phase separator in horizontal orientation consists of a shell, dished ends, and mostly two saddles. Determination of design temperature can follow the guideline below:if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_14',687,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0'); The separation process can be described as either a 2-phase or 3-phase vessel. Table 7.